Maximizing Efficiency with Warehouse Robotics in the Era of Supply Chain Disruption

In today's rapidly evolving supply chain landscape, the integration of technology is more crucial than ever, particularly in the realm of warehouse operations. The advent of warehouse robotics has emerged as a transformative solution to enhance efficiency and streamline processes amidst ongoing disruptions. As logistics face unprecedented challenges, including fluctuating demand and labor shortages, the deployment of automated systems not only mitigates these issues but also optimizes inventory management and order fulfillment. Companies leveraging warehouse robotics can significantly reduce operational costs and improve accuracy, leading to faster delivery timelines and enhanced customer satisfaction. This article explores the best practices in implementing warehouse robotics, emphasizing their role in maximizing efficiency and resilience in an increasingly complex supply chain environment.

Understanding the Impact of Supply Chain Disruption on Warehouse Operations

The impact of supply chain disruptions on warehouse operations has become increasingly pronounced, as organizations strive to navigate the complexities introduced by factors such as geopolitical instability, extreme weather events, and an ongoing pandemic. These disruptions challenge traditional warehousing strategies, forcing companies to rethink their approaches to inventory management and logistics. The rising demand for efficiency has intensified the focus on harnessing advanced technologies, particularly artificial intelligence and robotics, to enhance operational resilience.

As businesses adapt to this new reality, the implementation of digital twins and AI-driven analytics has emerged as a pivotal strategy. By creating virtual models of their supply chains, organizations can gain valuable insights into potential vulnerabilities and inefficiencies within their warehouse operations. This proactive approach allows for better forecasting and resource allocation, ultimately mitigating the impacts of crisis situations. Furthermore, strategic partnerships with third-party logistics providers can bolster agility and responsiveness, enabling companies to not only survive disruptions but thrive amidst them.

Key Technologies Driving Warehouse Robotics Efficiency

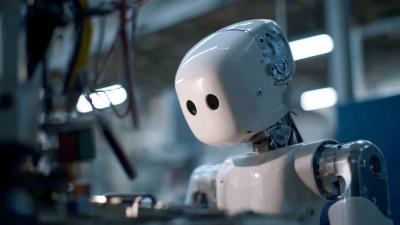

Warehouse robotics is rapidly transforming supply chain operations by integrating key technologies that enhance efficiency and accuracy. The adoption of advanced robotics systems allows businesses to streamline their workflows, significantly reduce labor costs, and increase overall productivity. With innovations such as AI-driven demand prediction and automated inventory management, warehouses can better respond to fluctuations in demand and optimize resource allocation. These technologies not only facilitate faster order fulfillment but also minimize errors, leading to improved customer satisfaction.

Moreover, the emergence of fully unmanned robotic solutions is pushing the boundaries of warehouse automation. Companies are increasingly introducing sophisticated robotic arms and autonomous mobile robots that handle a variety of tasks from picking to sorting. This technological evolution is essential for navigating ongoing supply chain disruptions, enabling businesses to maintain operational continuity. As the warehouse robotics sector continues to grow, the focus on integrating AI and robotics will be pivotal in redefining logistics and setting new standards for efficiency in the supply chain landscape.

Benefits of Integrating Robotics into Supply Chain Management

The integration of robotics into supply chain management brings a multitude of benefits, particularly in the face of recent supply chain disruptions. One of the most significant advantages is the enhancement of operational efficiency. Robotics can streamline repetitive tasks such as picking, packing, and sorting, allowing human workers to focus on more complex and strategic responsibilities. This shift not only reduces the likelihood of human error but also accelerates the overall workflow, making warehouses more responsive to fluctuating demands.

Additionally, warehouse robotics can significantly improve inventory management and accuracy. With advanced sensors and artificial intelligence, robotic systems can keep track of stock levels in real-time, reducing the chances of overstocking or stockouts. This dynamic oversight ensures that products are available when needed, thus improving customer satisfaction. Furthermore, the ability to analyze data collected by these systems allows businesses to forecast trends and align their supply chain strategies accordingly, ultimately leading to a more resilient operation in the face of disruptions.

Maximizing Efficiency with Warehouse Robotics in the Era of Supply Chain Disruption

| Benefit | Description | Impact on Efficiency (%) | Common Robotics Types |

|---|---|---|---|

| Increased Speed | Robots can operate continuously without breaks, significantly increasing order fulfillment speed. | 30% | Autonomous Mobile Robots (AMRs), Automated Guided Vehicles (AGVs) |

| Reduced Errors | Automation minimizes human error in picking and packing processes. | 25% | Picking Robots, Machine Vision Systems |

| Cost Savings | Long-term operational costs are reduced due to decreased labor needs and increased productivity. | 20% | Automated Sorting Systems, Robotic Arms |

| Scalability | Robotic systems can be easily scaled up to meet changing demands. | 35% | Collaborative Robots (Cobots), Automated Storage and Retrieval Systems (AS/RS) |

| Enhanced Safety | Robots can handle dangerous tasks, reducing workplace injuries. | 15% | Forklift Robots, Hazardous Material Handling Robots |

Challenges in Implementing Warehouse Robotics Solutions

The integration of warehouse robotics presents significant opportunities for enhancing efficiency in supply chain operations. However, implementing these solutions is fraught with challenges that must be meticulously navigated. One primary obstacle is the high initial investment required for advanced robotic systems. Companies often struggle to justify these costs amid fluctuating market conditions and supply chain disruptions, creating reluctance in decision-making.

Moreover, integration with existing systems poses another substantial hurdle. Many warehouses rely on legacy software and hardware, making it complicated to incorporate new robotic technologies. This technical debt not only prolongs the implementation timeline but may also require additional investment in training and system upgrades. Finally, workforce resistance to change can impede the seamless adoption of robotics. Employees may fear job displacement or may lack the skills necessary to work alongside these new technologies, necessitating a robust change management strategy and training programs to foster a collaborative environment.

Maximizing Efficiency with Warehouse Robotics

Best Practices for Maximizing Robotics Performance in Warehousing

In the era of supply chain disruption, warehouse robotics have become an essential asset for optimizing operational efficiency. By integrating advanced robotic systems into warehousing processes, businesses can enhance productivity, reduce human error, and adapt swiftly to changing demands. However, to fully harness the power of robotics, it's crucial to implement best practices that ensure maximum performance.

Tip 1: Invest in Training and Development

To optimize the usage of warehouse robots, ensure that your team is well-trained in operating and maintaining these systems. Continuous education on the latest technologies and robotics capabilities will empower employees to troubleshoot issues efficiently and maximize operational workflows.

Tip 2: Implement Data Analytics

Utilize data analytics to monitor the performance of robotic systems in real-time. Understanding patterns of efficiency and identifying bottlenecks can help in fine-tuning operations. By leveraging data, warehouses can make informed decisions that enhance the effectiveness of their robotic solutions.

Engaging in regular maintenance schedules is another key practice. Just like any machinery, warehouse robots require upkeep to function optimally. Establishing routine checks can prevent costly downtimes and ensure that robotic performance remains at peak levels.

Related Posts

-

Rethinking Robots: How Innovative Technology is Shaping Our Future Workspaces

-

Maximizing Efficiency with Logistics Robotics A Comprehensive How to Guide

-

Exploring the Future of Work with Think Robotics Innovations

-

Ultimate Guide to Mastering Agile Robotics for Business Success

-

How to Maximize Efficiency with AMR Robots: Insights from the 2023 Logistics Automation Report

-

Challenges Faced by Industries Embracing Robotics and Automation